High Gloss Acrylic Shower Wall Panels

Benefits of High Gloss Acrylic Shower Wall Panels & Backsplashes

Swipe or click and drag to view all images.

-

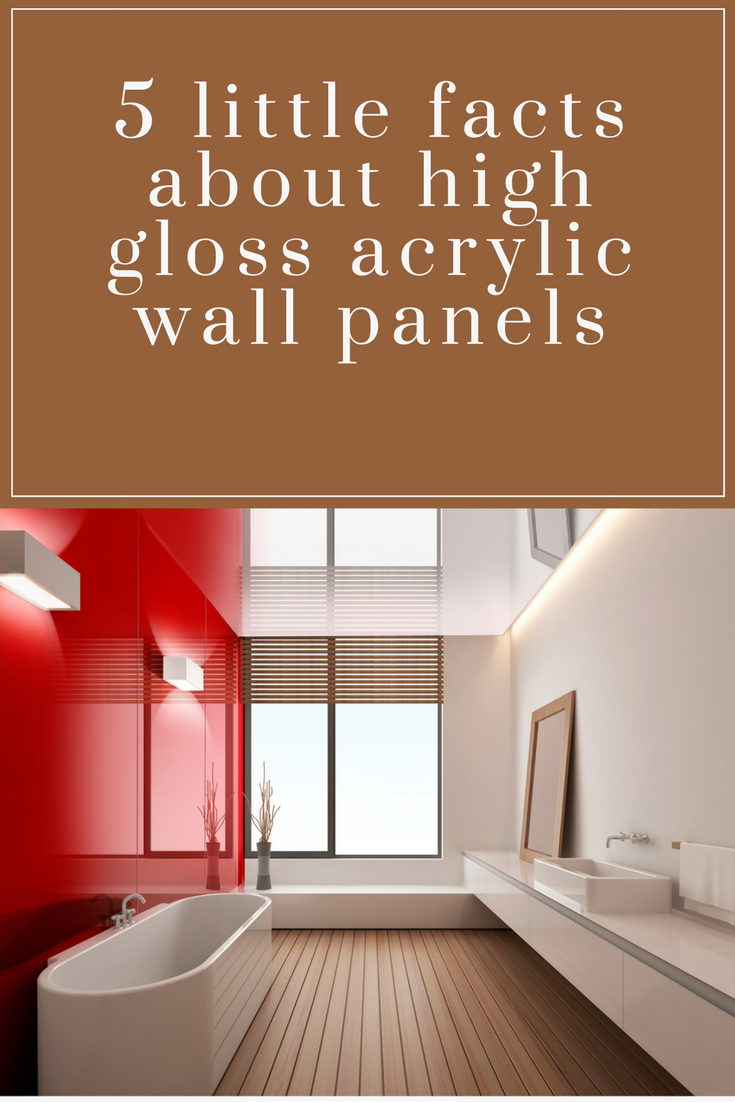

Creates a clean, contemporary lookThe high gloss acrylic shower panels and colored acrylic kitchen panels create a fresh clean European look with a luxurious and elegant finish.

-

Unique colors adds a stylish touchChoose from a wide range of fun colors like arctic white, blue atoll, glacier, carbon black, red rouge, and titan gray to dress up any indoor residential or commercial space.

-

Flexible material can be used for more than just showersHigh gloss panels from Innovate Building Solutions can be used in bathrooms, bedrooms, media rooms, hallways, reception desks and commercial lobbies to name just a few rooms. Cool, eclectic and exciting are just some of the words used to describe these panels.

-

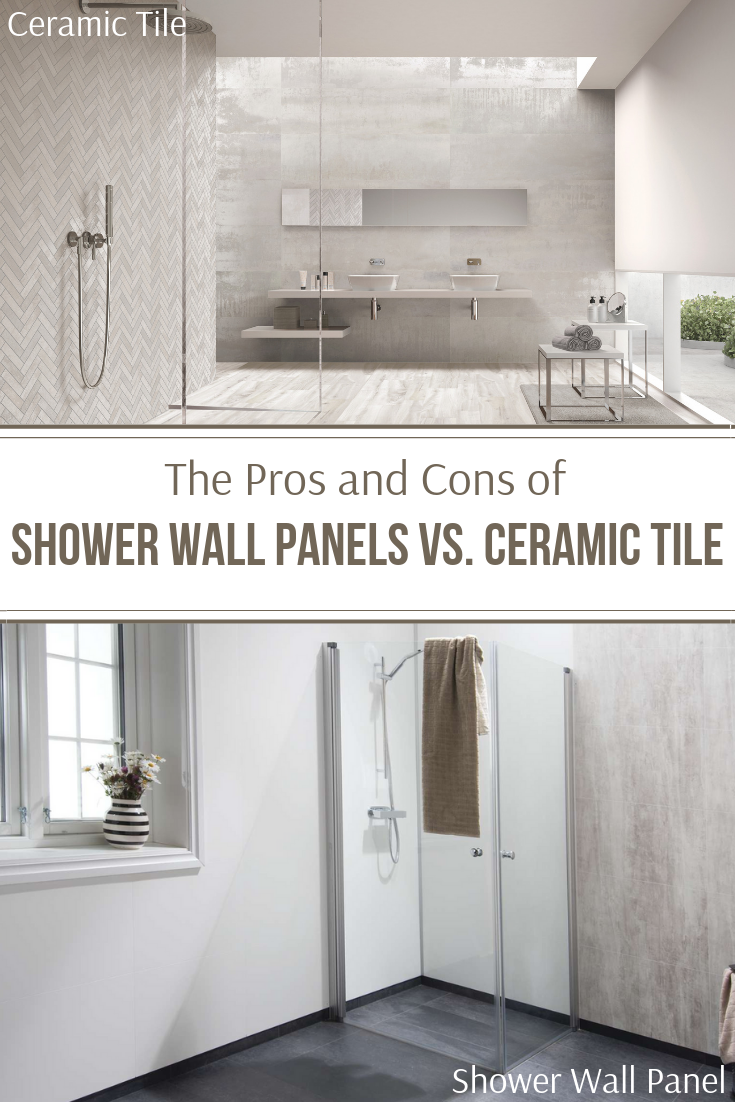

Easy to clean with no grout to maintainWhile tile is the most commonly used material in shower and tub wall panels and kitchen backsplashes most people hate the cost and hassle of cleaning and resealing grout! With these innovative acrylic shower wall panels you’ll get a sleek euro look and eliminate the effort and cost of maintaining grout. These smooth/non-stick walls are easily cleaned with warm water and a soft cloth.

-

Glass type look with the benefits of acrylicHigh gloss acrylic backsplashes and shower panels are 25 times tougher than glass with 1/2 the weight.

-

More cost effective than back painted glassBack painted glass – while very stylish – will be 2 times as expensive as high gloss acrylic shower panels and acrylic backsplashes.

-

Durable long lasting materialHigh resistance to UV light, cracking and chipping makes this is popular materials vs. glass, ceramic tiles, aluminum or wood.

-

Simple installation processThese high gloss acrylic panels can be cut drilled and shaped with common woodworking materials and the panels can be set with double sided foam tape and neutral cure silicone. Installation will take 1/3 of the time of a tile job.

-

100% waterproofIn wet applications likes showers, tubs and backsplashes it’s nice to know with high gloss acrylic shower panels and acrylic backsplashes you don’t have to worry about moisture growing behind the wall. The panels are waterproof on the surface.

-

One size panel for design flexibility

Only availble in 2 standard panel sizes (60″ x 96″ and 48″ x 96″)

-

Nationwide supply for DIY’ers or professional installation serviceIf you’re a DIY person Innovate Building Solutions can wholesale these panels direct to you and provide free nationwide shipping as well. On regional basis we provide professional installation service as well.

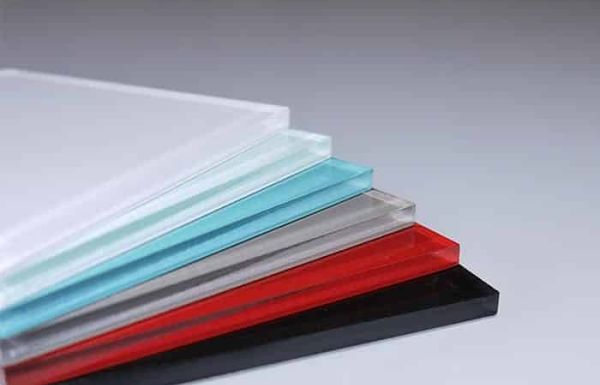

Acrylic Wall Panels

High gloss acrylic shower panels and backsplashes – These acrylic wall panels have a mirror like finish with an integrated fused color layer behind a thick optical grade clear acrylic layer. The material is coated in a high performance micro hard coat on the outer surface for extra scratch resistance.

Where to Use High Gloss Wall Panels?

Residential – shower and tub wall surrounds, kitchen and bathroom backsplashes, ceilings, bedrooms, media rooms, cabinet doors and hallways, and ceilings to reflect light.

Commercial – reception desks, lobby areas, classrooms (for whiteboards), hallways, around elevators, offices and conference rooms.

Signage and exhibition – company signs (on the inside of the building) and trade show exhibits.

Standard Panel Size

The following standard sized panels are available for either new construction or remodeling projects:

- 60″ x 96″ (5/32″ thickness) – perfect for shower wall back panels and larger areas you need to cover.

- 48″ x 96″ (5/32″ thickness) – perfect for the sides of your shower walls and larger areas you need to cover.

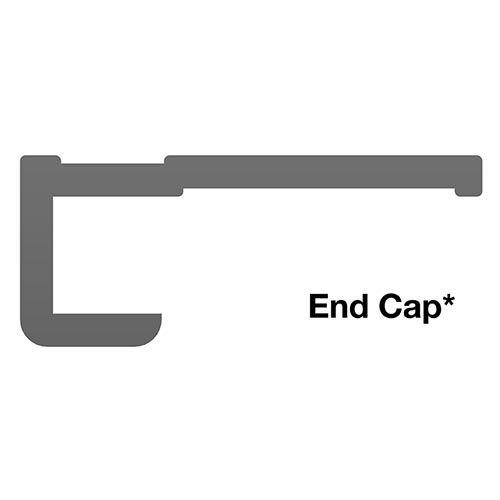

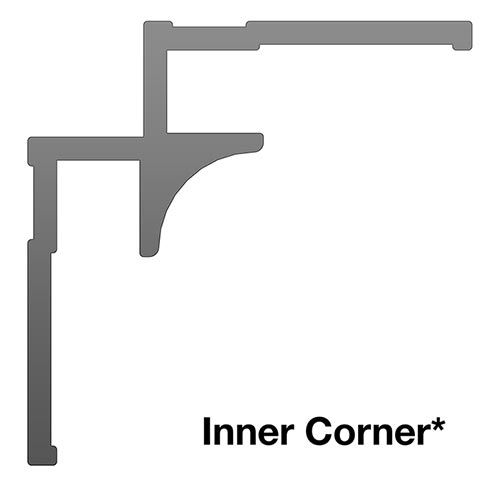

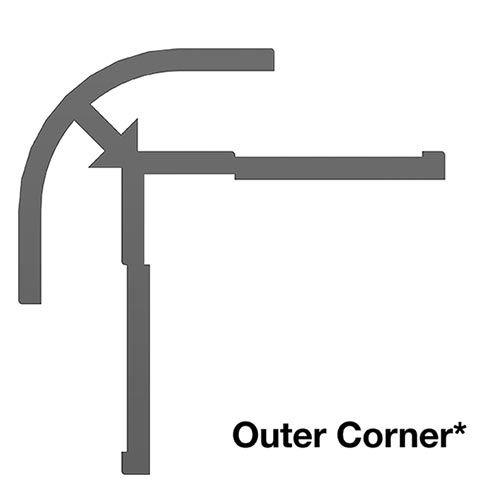

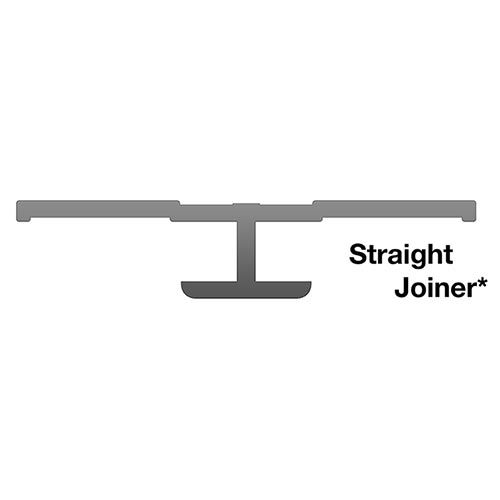

Edge Finish Trim Options

High gloss acrylic shower panels can either be placed close together with a 1/8” joint sealed with neutral cure silicone or you can use either anodized aluminum or aluminum color matched profiles which are matched to your wall panel can be used to join straight sections, corners or finish the edges.

Installation Kits

An installation kit can be purchased for your high gloss walls. The kit includes 2 tubes of neutral cure silicone, double sided tape, spatula, spacers, gloves, sandpaper and a cleaning tool.

High Gloss Acrylic Color Options

Arctic

Carbon

Glacier

Rouge

Safari

Titan

Azure

Installing Lustrolite Acrylic Wall Panels

These high gloss acrylic panels can be cut drilled and shaped with common woodworking materials and the panels can be set with double sided foam tape and neutral cure silicone. Installation will take 1/3 of the time of a tile job.

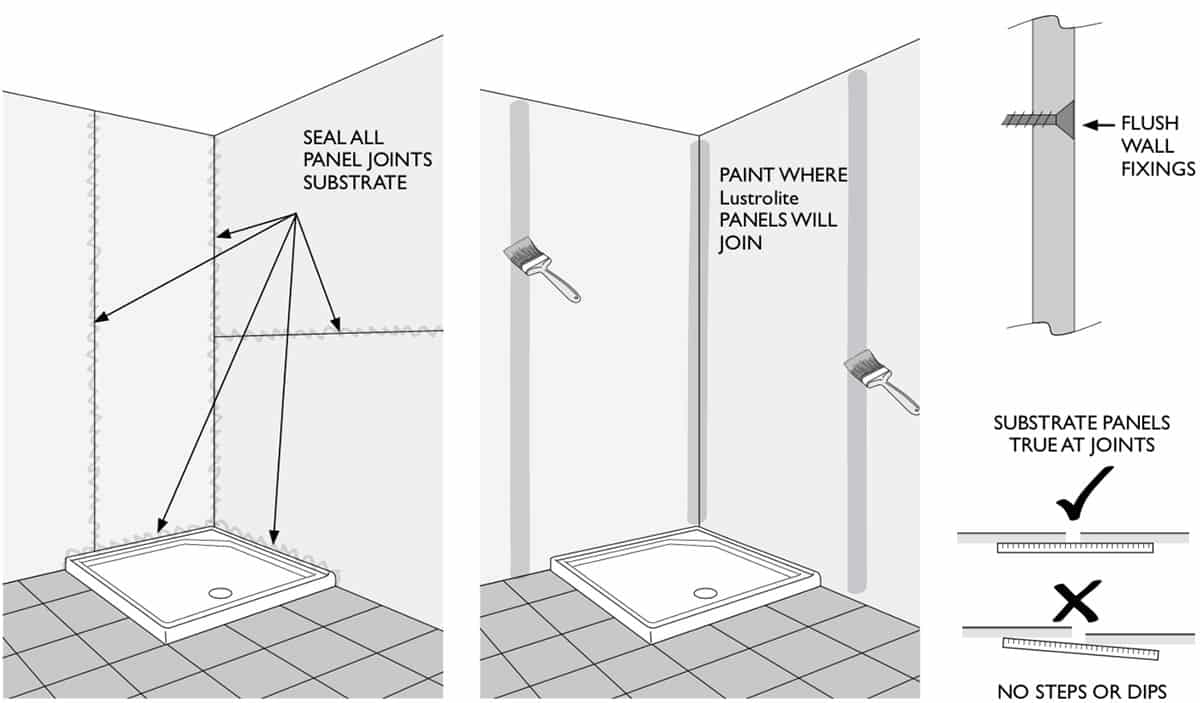

Step 1 – Preparing the walls for your high gloss acrylic shower and backsplash panels

- Make sure the walls are smooth, clean and dry.

- All wall backer materials should be flush (nothing sticking out). Make sure shower and tub wall backer materials meet local building codes.

- Seal all joints between your wall backer material.

- Where there will be a joint between your high gloss panels paint the wall backer a similar color to your wall panels.

Step 2 – Measuring and determining the right size high gloss acrylic shower wall panels to use

- Measure the entire area you’d like to cover and determine the largest panels size(s) to cover this area.

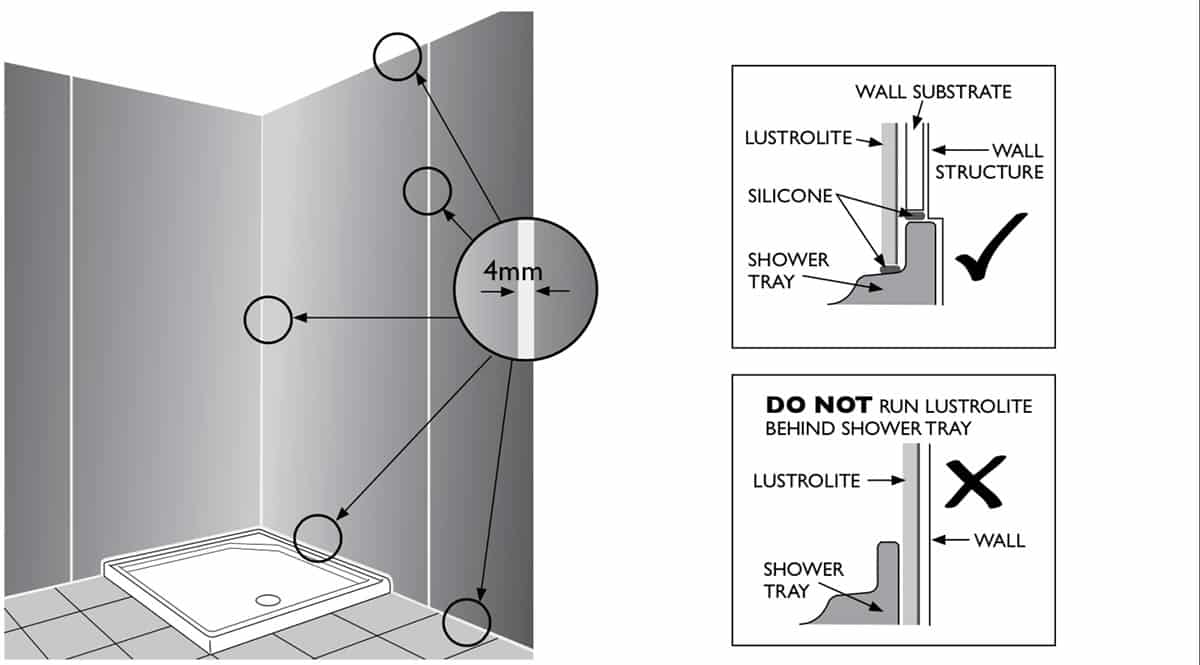

- Allow for a 5/32” joint between the wall panels and at the corners.

- Check to make sure the walls are square.

Step 3 – Marking your panels for holes and cuts

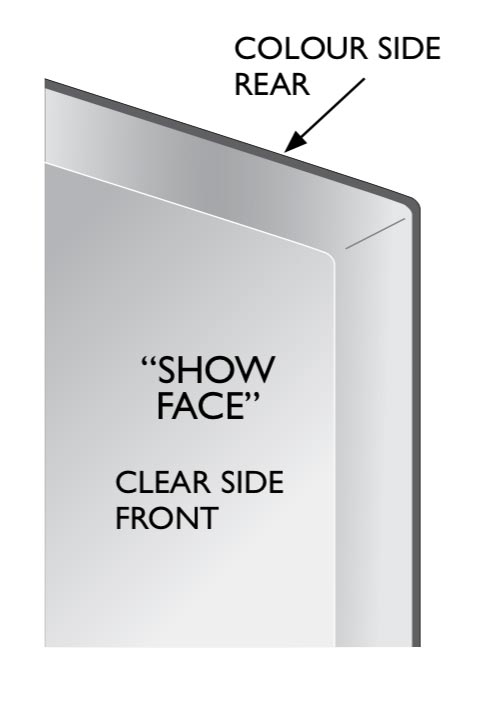

- At this stage leave the protective film on both sides of your panels. (note: the color side is on the rear and the clear side will be the front surface of your completed walls).

- Mark all the holes and cuts on the film with a felt tip pen (do not make markings in very hot or cold conditions because thermal expansion and contraction can affect final panel sizes.

- Do not remove the protective film on the front of the panel until the installation is completed.

Step 4 – Cutting the acrylic panels

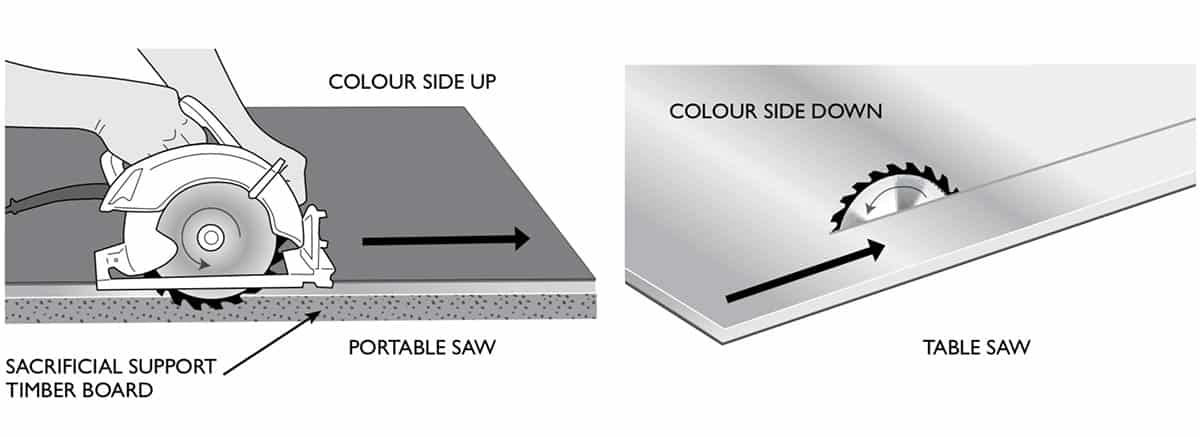

- Clamp the panels on a plywood sheet or solid table top to avoid chipping.

- With a circular saw use a fine sharp blade to create a straight and accurate cut. This blade should be suitable for plastic or aluminum. A carbide tipped blade with 8 to 12 teeth per inch is best.

- When using a portable circular saw cut with the color side of the high gloss sheets facing UPWARDS. If using a fixed table circular saw cut with the color side facing DOWNWARDS.

- Only use a jigsaw to cut short distances like for electrical openings. Only use blades suitable for aluminum or plastics.

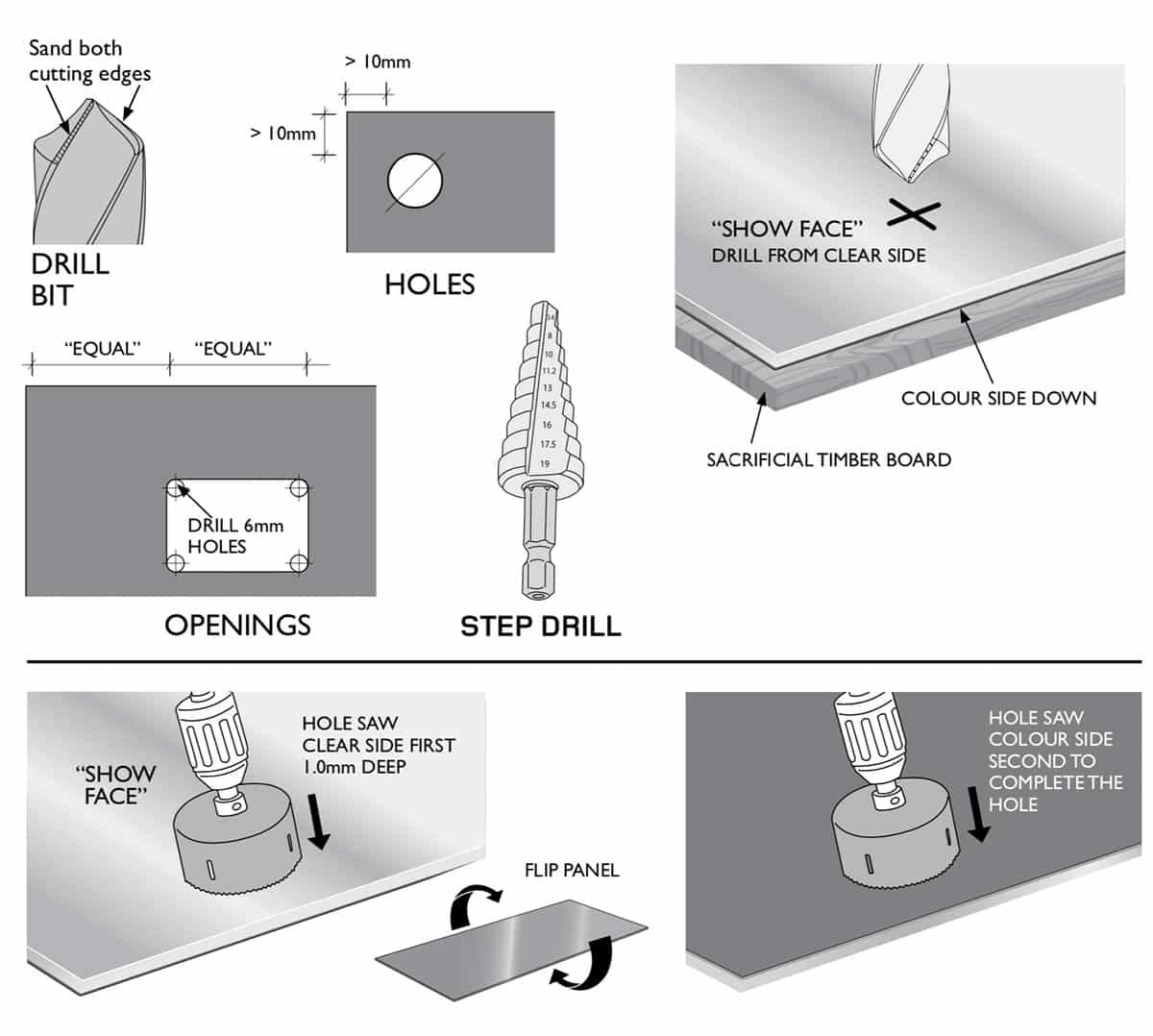

Step 5 – Drilling the acrylic panels

- Drilled holes should be no closer than 3/8” from the edge of the panel sheets. Put a piece of wood underneath the cut.

- Use a slow to medium speed drill with a slightly blunt drill bit. Drill from the finished face side (clear side) to reduce the risk of chipping.

- For larger holes use a fine toothed hole saw.

- Step drills are ideal for mid sized holes or for making smaller holes larger.

Step 6 – High gloss acrylic panels installation process

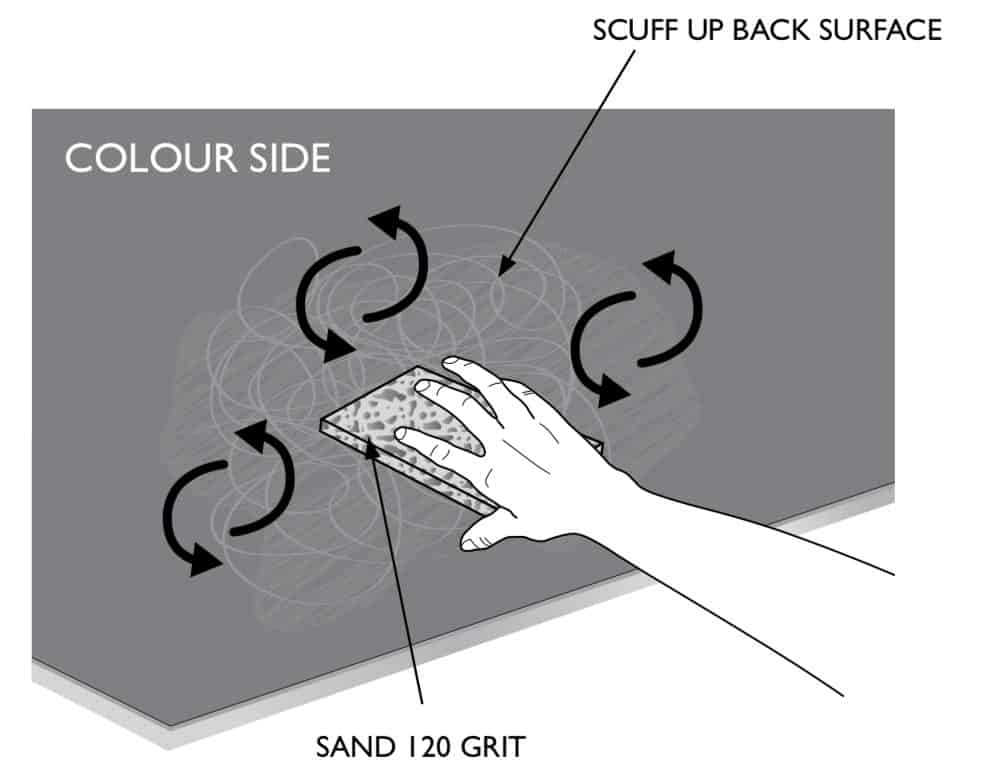

- Remove the protective film from the rear surface (color side). Do not remove the protective surface on the front (clear side) of the panel at this time.

- Scuff the rear surface with a course scouring pad or 240 grit sandpaper.

- Make sure the rear surface is clean and free of dust.

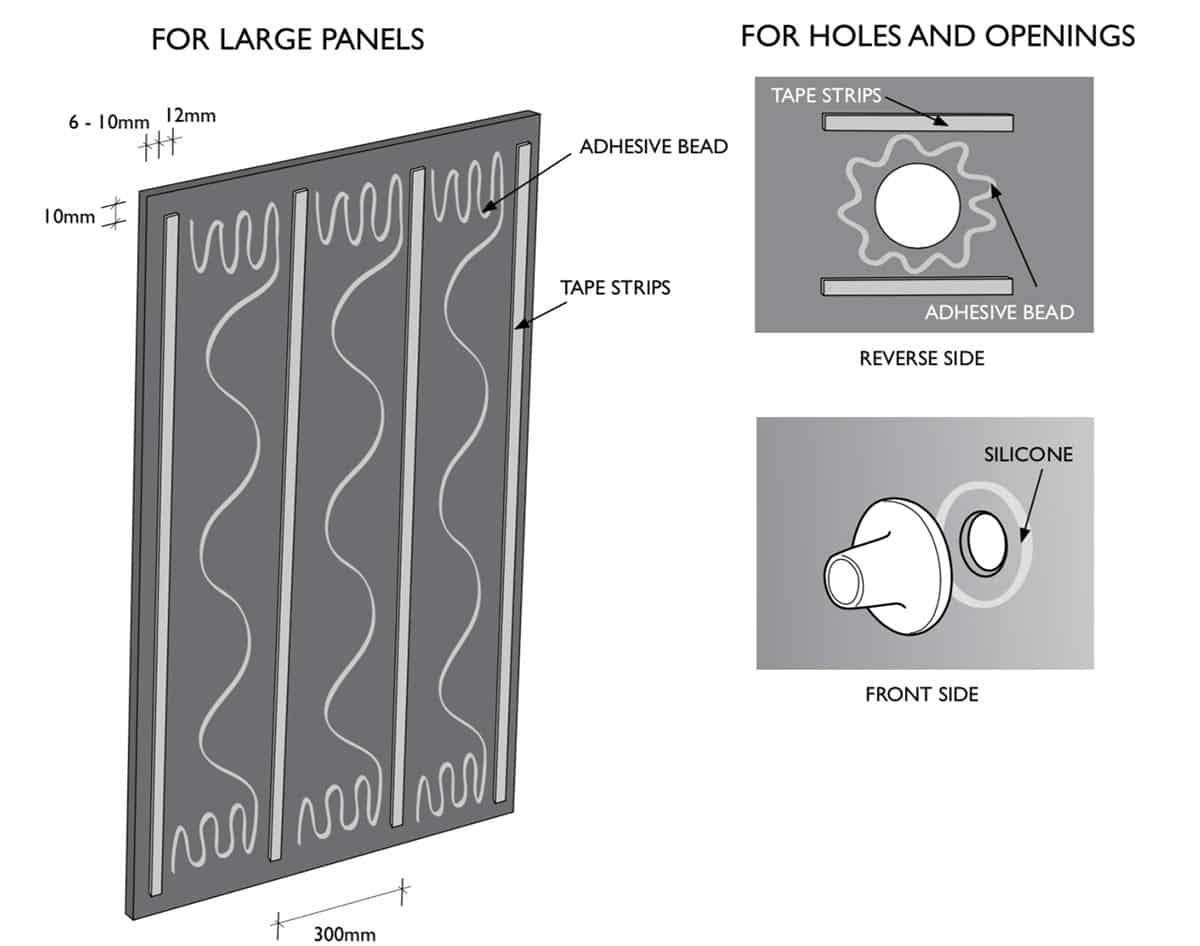

- Apply 1/2” x 1/16” thick double coated polyethylene foam tape with a synthetic rubber adhesive on the rear surface of each panel at approximate 12” spacing.

- Apply 1/4” bead of translucent neutral cure silicone in a wavy pattern between each tape strip. Near the edge of the panel increase the wavy pattern. Run a bead of silicone around any hole or cut out.

- Remove double sided tape liner on the back.

- Install the panel by resting on spacers at the bottom and between the panels.

- Firmly rub down panel to ensure tape bonds and adhesive contacts the wall. Allow to cure for 24 hours.

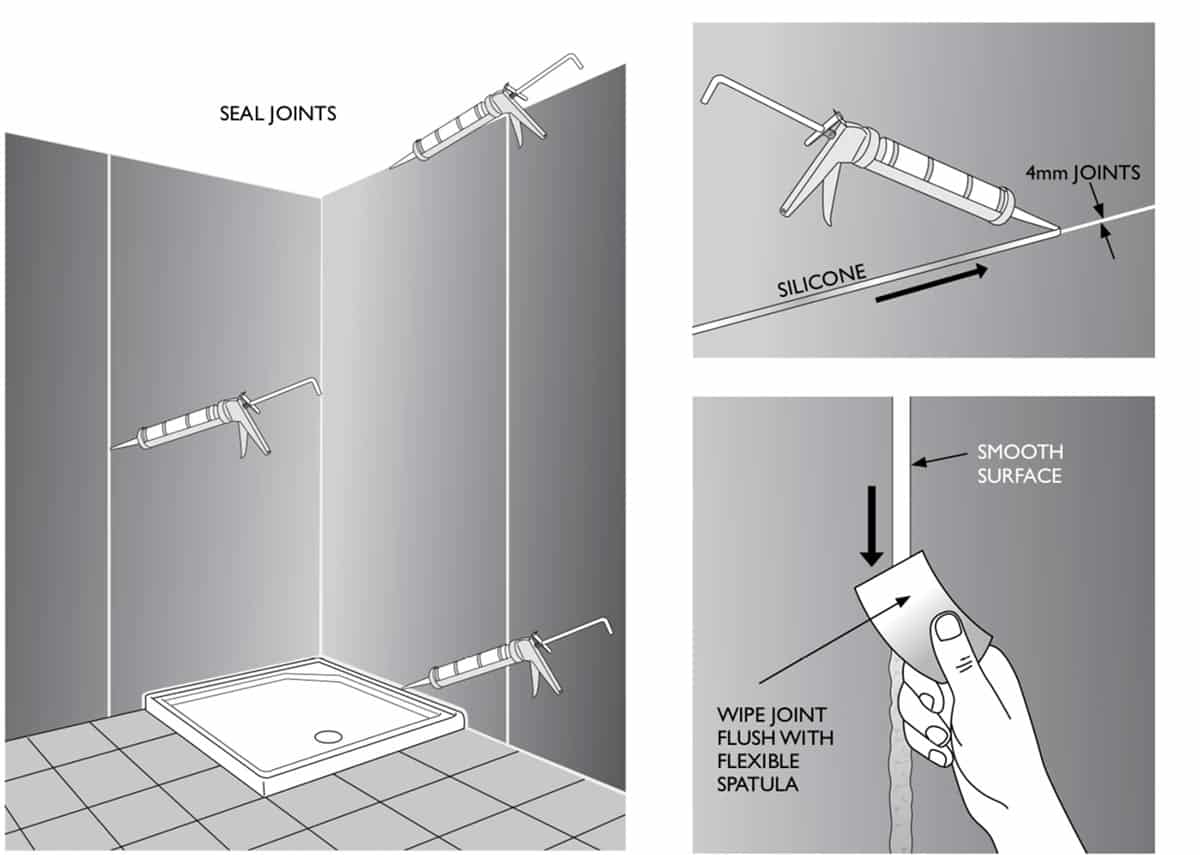

- Seal the joints with neutral cure wet area silicone.

- Once the gap is filled remove the excess silicone using a soft flexible plastic spatula.

- Immediately after the silicone is made flush remove the outer protective film.

Step 7 – Cleaning

- Use a soft microfiber cloth or chamois with non-abrasive detergent in warm water. Grease or oil can be removed with suitable plastic cleaners.

Note: Do not rub the Lustrolite surface when it’s dry. Do not use brushes or scouring pads on the high gloss surface.

Frequently Asked Questions About Acrylic Shower Panels

High gloss panels can be used for a backsplash, shower or tub wall, bathroom, bedroom or media room. High gloss wall panels should not be used directly behind a heat source above 158 degrees Farenheit. For these areas consider using stainless steel or ceramic tiles.

Lustrolite high gloss acrylic shower panels can be cut with standard woodworking tools – so contractors and homeowners who are familiar with these tools can certainly work with the gloss panels. The following tools are best:

- Jig saws – curved cuts

- Circular saw or track saw– long, straight cuts

- Hole saws – larger holes

- Step drills – mid sized holes

- Drill – smaller holes

A simple pass with an electric planer (or sanding with a medium and fine sandpaper) will provide a nice finished edge. Another alternative is to use the anodized aluminum edge finishing pieces or to use the polished finished factory edge on the outside.

After test fitting the panel on the wall remove the protective film from the back (the color side) to apply the double sided tape and neutral cure silicone. The tape on the front (the clear side) should be removed after the silicone is made flush on the front.

Clean with a soft cloth with warm water and mild detergent. Do not use strong chemicals or window cleaning spray.

The panels can be repolished using a liquid plastic polish.

Moderate scratches can be removed with manual buffing – use a smooth circular motion.